The full-hanging automatic set stage acoustical shell is a whole new type one, which is to hang all the reflective panels including rear ones, top ones and side ones of the stage acoustical shell on the stage fly bars, so that the acoustical shell can be quickly set or retracted, so as to achieve a rapid change between natural sound performance and electric sound reinforcement performance program.

The stage acoustical shell is composed of three parts which are the rear panels, the top panels and the side panels, There are several types of the three parts to set a shell, But until now there is no kind of side panels of the acoustical shell that is hanging on the fly bars. There is usually a cart type, or a type hanging on the wings platform, which causes the side panels to be set very slowly, led to the setting of the acoustical shell is a slow process, even if it is set very efficiency, it still takes about 30 minutes, As a result, the use of the acoustical shell could not be inserted throughout the performance, and it was impossible to quickly change the scene between the electric sound reinforcement performance and the natural sound performance, because the change of the scene needed to be completed in a few minutes. Therefore, until now, the use of the traditional stage acoustical shell is set in advance in the whole performance, and then the whole scene is a natural sound performance, which has caused big limitations, because usually most of the theater stage performance are mainly based on electric sound reinforcement performance, supplemented by natural sound performance, in which the type and number of natural sound performance programs should be based on the natural sound amplification conditions of the scene, if the conditions are not ideal, the number of natural sound performance will be decreased or even be canceled. One of the most advantageous natural sound performance conditions is that the stage has a set of stage acoustical shell, As there was no the stage acoustical shell with a quick change of scenes before, the natural sound performance with small sound pressure cannot be carried out.

Therefore, the full-hanging automatic stage acoustical shell that can be quickly set and retracted provides a revolutionary innovative product for theater stage performance, which can truly meet the requirements of most theater stage performance types and create conditions for interspersed with various natural sound performance, which not only achieves the rapid change of scenes that cannot be done by traditional acoustical shell in the past, but also saves the ground space on the stage because the acoustical shell is all hanged above the stage, especially for smaller theater stages, which is very suitable.

The fold and unfold of the side panels of the stage acoustical shell is the key to affecting the time of set and retract. Because when the side panels are lift, if they cannot be folded up, they will collide with various lights and other equipment hanging on the fly bars, and this problem has not been solved before. For a long time, the side panels of traditional acoustical shell use a cart type, each panel is a cart, because the side panels are high and have a certain weight, for safety and stability, each cart has a counterweight underneath. When in use, it should be pushed to the stage from the side of the stage, and the top panels and the rear panels are built next to each other with the side panels, and when not in use, it should be pushed to the side of the stage, and the setting and putting away is a long manual operation time process, and often to scratch the floor. and the side panels also occupies a lot of stage space. The trolley type of the side panels of acoustical shell is in a wide range of use, and another type that side panels of acoustical shell hanging on the wings platform requires the wings platform to have enough space, especially the height of the platform, and needs to have a guide rail that extends from the wings platform to the center of the stage, and then unfold it after pushing it to the center, and when it is put away, it is necessary to fold and push back to the side, and the operation also takes a long time, wherein the height of the guide rail is a big problem.

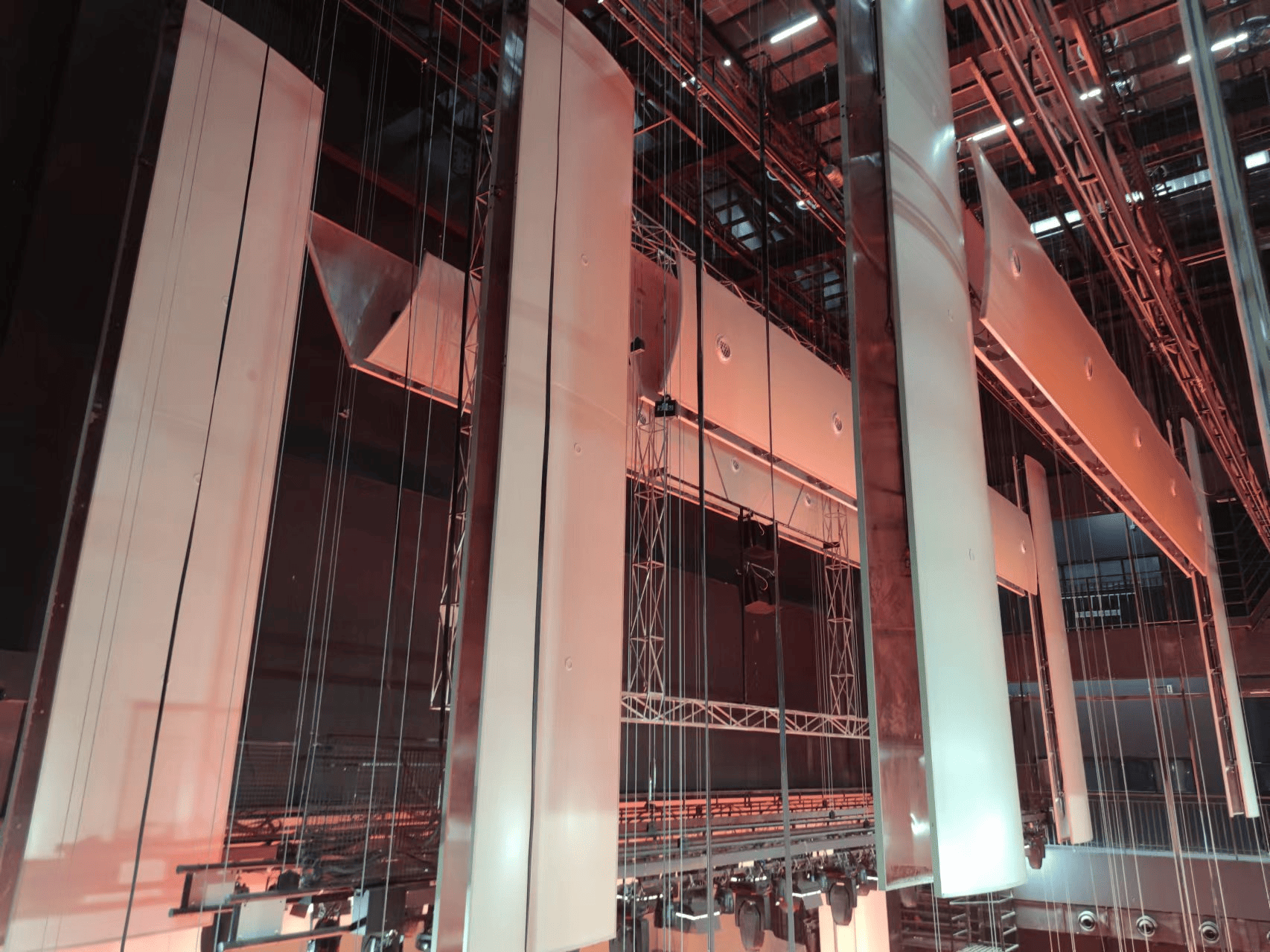

The side panels of the full-hanging automatic set stage acoustical shell are hanged on the fly bars, and in the case of not using, it is lifted on the fly loft above the stage, every two pieces in a group, in a folded state, and there is a reasonable distance between the side panels and the surrounding stage lightings and other equipment on the other fly bars, and it will not lead to collide, when used, the fly bars hanging the side panels descends to a certain extent, and the folded side panels are opened automatic and are built together with the descending top panels and the rear panels to form a set of complete stage acoustical shell. The opening process uses the mechanical principle of automatic opening according to gravity, After the use is completed, the fly bars are lifted upward, and the opened side panels are gradually folded upwards to return to position, which is also a mechanical lifting method that does not use electrical devices, so as to be simple, reliable and practical.

With automatic programming, the opening or closing time of the acoustical shell can be reduced to 2 minutes and a half, respectively. Automatic programming is a particularly important one, because the retraction and release of the multi-channel acoustical shell fly bars requires very skilled operation, and the entire manual operation process is carefully optimized many times, and then the automatic programming is carried out to form a fully automatic operation mode, which is a one-key operation, which eliminates human uncertainties, saves time, effort and labor, and is safe, reliable and fast.

In addition, not only the side panels, but also the top and rear panels of the full-hanging automatic set stage acoustical shell system have more important improvements compared with the traditional method. This is due to the fact that the opening shape of the acoustical shell is the most suitable curved bell shape to better match the sound diffusion and avoid eddy currents and other factors, resulting in a stronger sound pressure output (see the video below). In this way, the stage machinery manufacturers put forward very strict requirements for the design and installation of cooperation, although the traditional roof and rear plate suspension and retraction is a relatively perfect technology, but according to the traditional hoisting mode it is still unable to achieve the shape of the curved bell mouth.

In order to create the shape of bugle and easy to facilitate adjustment, a superior mechanical design has been carried out so that the positions of the three panels, the rear panels, the side panels and the top panels of the full-hanging automatic acoustical shell are adjustable. Achieve perfect interaction with the stage machinery producers.

As a complete new and remarkable technical system, the full-hanging automatic stage acoustical shell, is sure to provide a bright future for global stage equipment in the future.